Micro LED,将LED背光源微缩化、矩阵化,致力于单独驱动无机自发光(自发光)、让产品寿命更长,尺寸微小,maicro LED晶片长度约1~10μm,仅为 LED的1%,通过大规模转移技术,μm级三色RGB Micro-LED被转移到基板上,形成各种尺寸的Micro-LED显示屏。

中科Micro LED产品优势

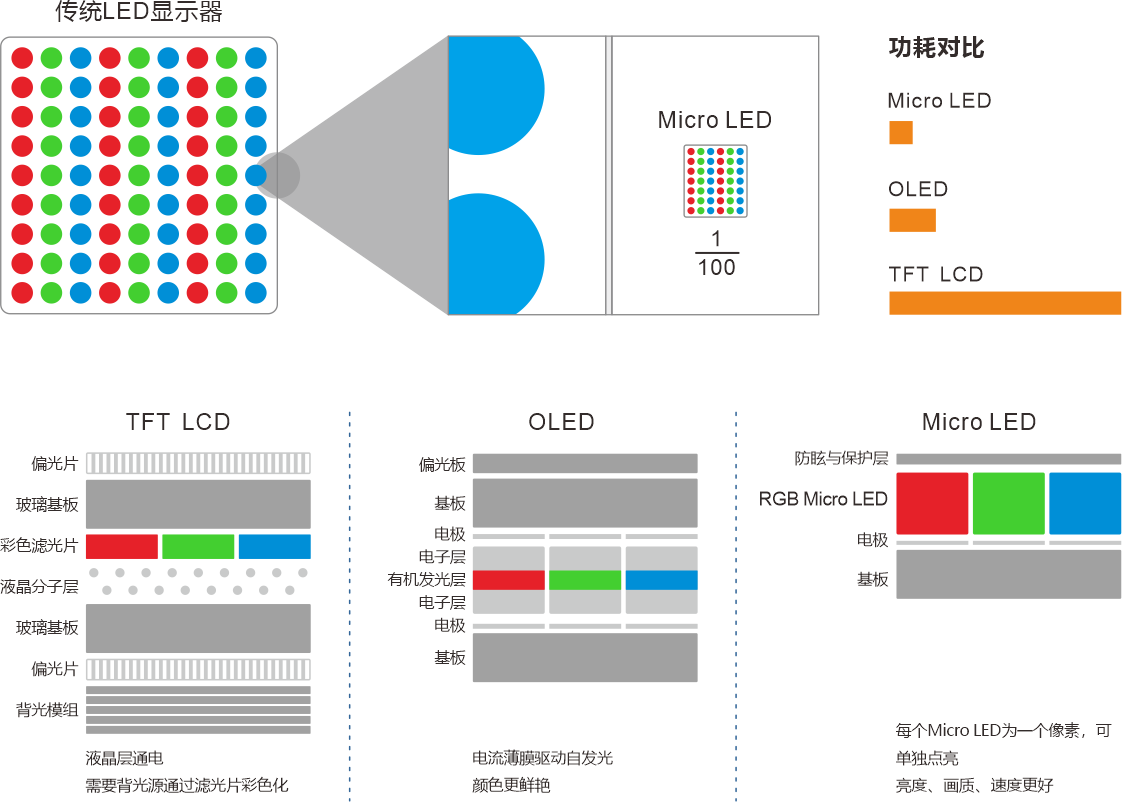

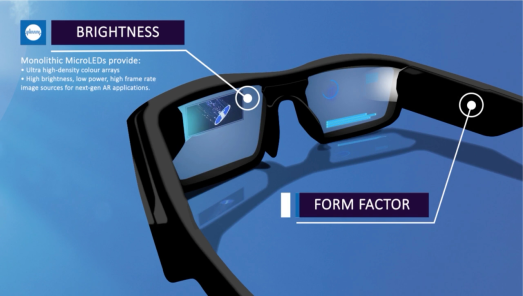

1. 高亮度、低功耗、超高解析度与色彩饱和度。

2. 几乎无光耗,寿命长和稳定性。

3. 材料稳定性较佳且无影像烙印。

4. 高速响应,高速调变、承载讯号,具有可视光无线通讯功能。

5. 适应各种尺寸。

6. Micro LED微显示器自发光,无需外加光源,节约成本。

7. 无缝拼接。

8. 应用范畴广。

Micro LED 显示屏

典型器件制备特点

典型尺寸1-100 微米,阵列制备,与驱动集成

典型尺寸300-1000微米,功率较高

外量子效率

工作在低电流密度下:相对较低

工作在高电流密度下:相对较高

工作在较高电流密度下:相对较低

可靠性

面向显示应用,高于传统LCD、OLED显示;面向 通信应用,在高达kA/c㎡电流密度下可靠性良好

面向照明应用,高于传统照明设备

光电调制带宽

数百MHz到>1 GHz

一般5-20 Mhz

与传统LED显示屏比较,Micro-LED的差别主要在于:

1.精密程度数十倍的提升;

2.集成工艺从直插、表贴、COB封装等变成了“巨量微转移”;

3.缺陷可修复性几乎为零;

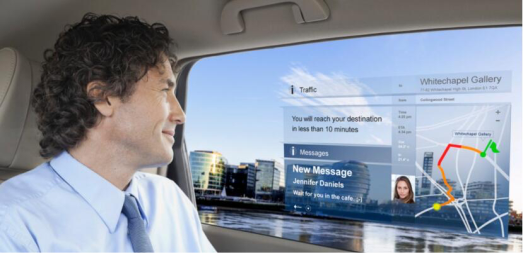

市场应用:超小型显示器、穿戴式设备、超大室内显示屏幕外,头戴式显示器(HUD)、抬头显示器(HUD)、车尾灯、无线光通讯Li-Fi、AR/VR、投影机等多 个领域。

智能眼镜显示系统

VR显示系统

军用头盔显示系统

高像素PPT显示屏

未来汽车玻璃显示系统

智能穿戴显示系统