工业互联网-微波智能工厂测试解决方案

发布时间:2019-11-25 06:17:46

十九大报告指出,要加快建设制造强国,加快发展先进制造业,推动互联网、大数据、人工智能和实体经济深度融合。因此我国的制造业也面临着一个很大的转型。目前制造业转型的一个很重要的标志就是实现智能化,对应到制造业就是智能工厂,将与制造相关的生产要素都实现数字化。同时,通过工业互联网和大数据等技术进行相应的互联,包括工厂,企业与企业之间,企业与客户,企业与供应商之间的关系,从而实现整个产业链的互联,提升整个产业链的价值。

目前传统工厂面临的问题:工厂在生产过程中,经常会因为原材料的问题导致生产良品率很低,以往对于原材料不良品的监测更多靠人眼识别,不仅耗时耗力,本身也容易产生错误。再者就是产量大的问题,使用人工进行实时数据更新也较为困难。

因此针对这样的情况,中科联合旗下中科艾美森工业系统产品线从三个方面为智能工厂设计开发了一套微波智能工厂测试解决方案。

第一:实现从业务到数据的转变;根据工厂的特点“量体裁衣”进行适合的数字化转型,把整个生产所涉及的业务单元进行数字化统一,建立相关的信息化系统。

第二:实现各个业务单元之间的互联;利用工业互联网、大数据的技术结段,打造一个整体数字化平台,实现数据向大数据的转变。

第三:实现整个业务和数字的高度融合;通过数字驱动来进行业务创新。

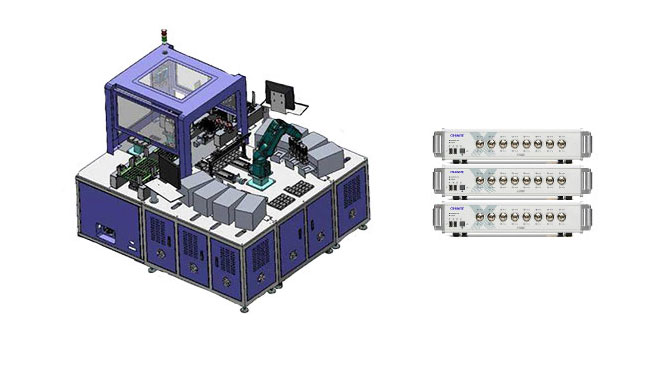

(无线芯片测量强化学习机器人与生产可视化)

中科艾美森.微波智能工厂自动化测控系统

系统介绍:

70M~70GHz自动化测量仪器系统,适用于无线自动化生产测试,包括BT、WIFI、NB、2G、3G、4G、5G、24G等模块的生产测试。日产模块25万只先进的智能化无线测控系统仅是同行10%测试成本。

工业4.0远程无线测控,每台机器人(工业化产线机械臂),通过远程控制完成大规模无线产品生产测试,让生产效率与质量成倍提升,先进的高速贴片线与测控系统每日产能200万点。

大屏实时输出当日每小时产测数量,包括各个工厂的产测数量,输出当日总产出、站点、生产型号和不良率,方便生产管理人员进行实时数据监控,确保产能。

结合案例:

2015年初成功实现首台70M~6GHZ自动化测量仪器系统投入量产,致今已陆续装配出60台仪器,成功实现日产量20万(PCS);

同类仪器市场售价30万元/台;间接为公司直接减少投入1800万元,打造自主知识产权的智能化无线测控系统。

型号:CT-UNITE W100

测试方法:协议测试

测试频率:70MHZ~6GHZ

测试效率:每次8PCS/10秒

测试产品:NB-IOT,802.11ac,蓝牙,4G,5G无线模块

产能/1H:2万(PCS)